AUTOSCREEN

Automated Screen Frame Solution Machines

Automate window screen fabrication with an AUTOSCREEN™ Machine

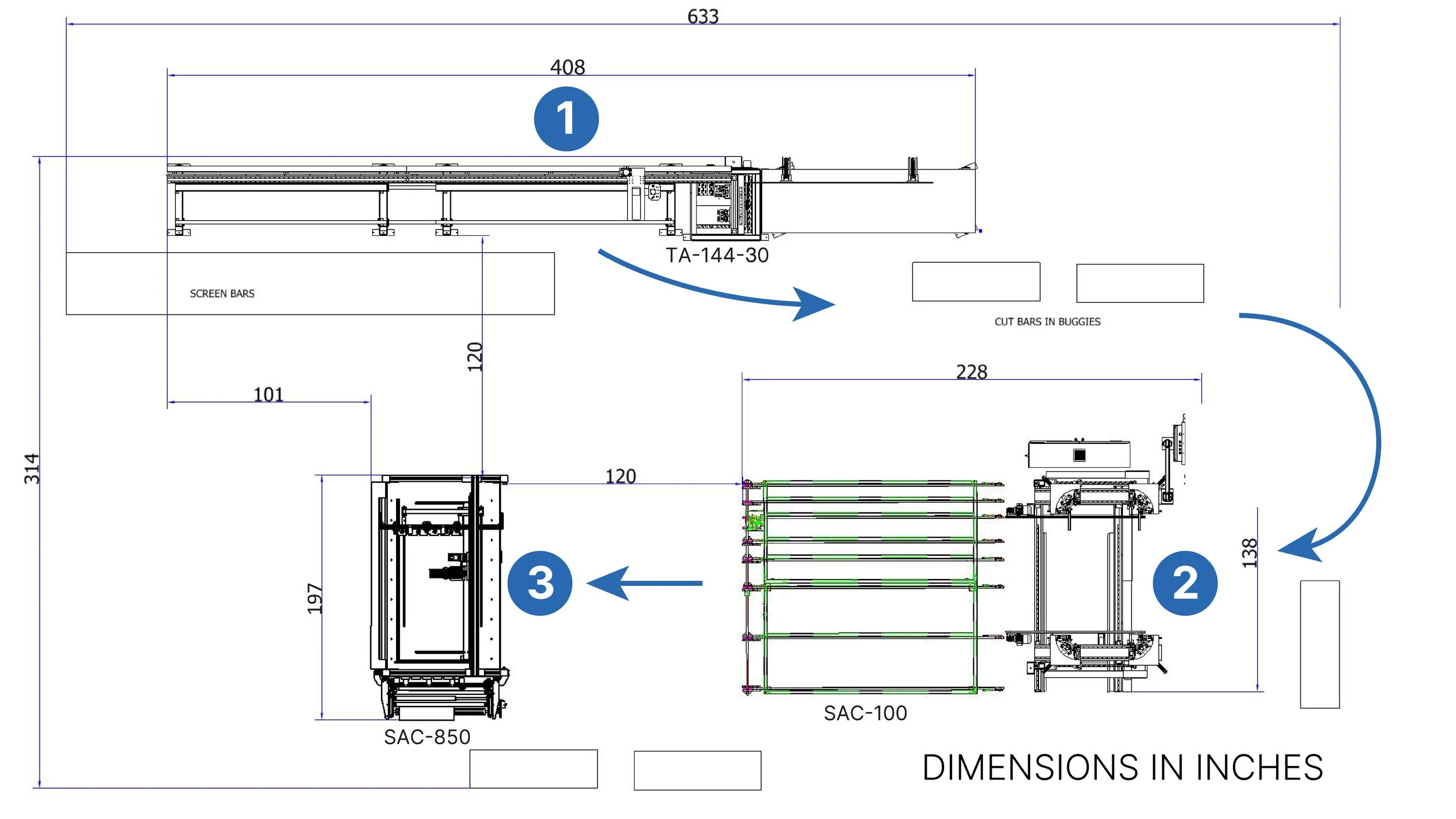

1

TA-144/30

Cut Your Profiles

Utilizing proprietary optimization software and a generic CSV-mapped format, this saw automates and optimizes the cutting of all screen frame profiles.

2

SAC-100

Assemble Your Frame

By scanning bar code information or through direct input into the CNC control, this automated press will accurately, consistently, and simultaneously position itself to assemble all four screen frame components at once.

3

SAC-850/855

Insert Screen Mesh

The SAC-850 and 855 automate the application of screen mesh to a pre-assembled screen frame — now with new patio door capabilities.

SAC-850/855

40 Seconds

Hung window

24" x 36"

50 Seconds

Casement window

48" x 60"

80 Seconds

Patio door

48" x 96"

Combatting the labor shortage one screen at a time

The AUTOSCREEN™ machine, with patio door-sized screen capabilities, can produce up to 1000 screens per shift, with 3 operators. Increase yields and profitability. Eliminate RSI, Repetitive Stress Injury. Allocate labor efficiently

Request a Demo

Optimize your screen manufacturing times and allocate labor effectively with Haffner’s AUTOSCREEN™ machines. Contact us today to learn more about the automated 3-step fenestration process.