SAC-845/855

Now with patio door capabilities

40 seconds

Hung Window

24” x 36”

50 seconds

Casement Window

48” x 60”

80 seconds

Patio Door

48” x 96”

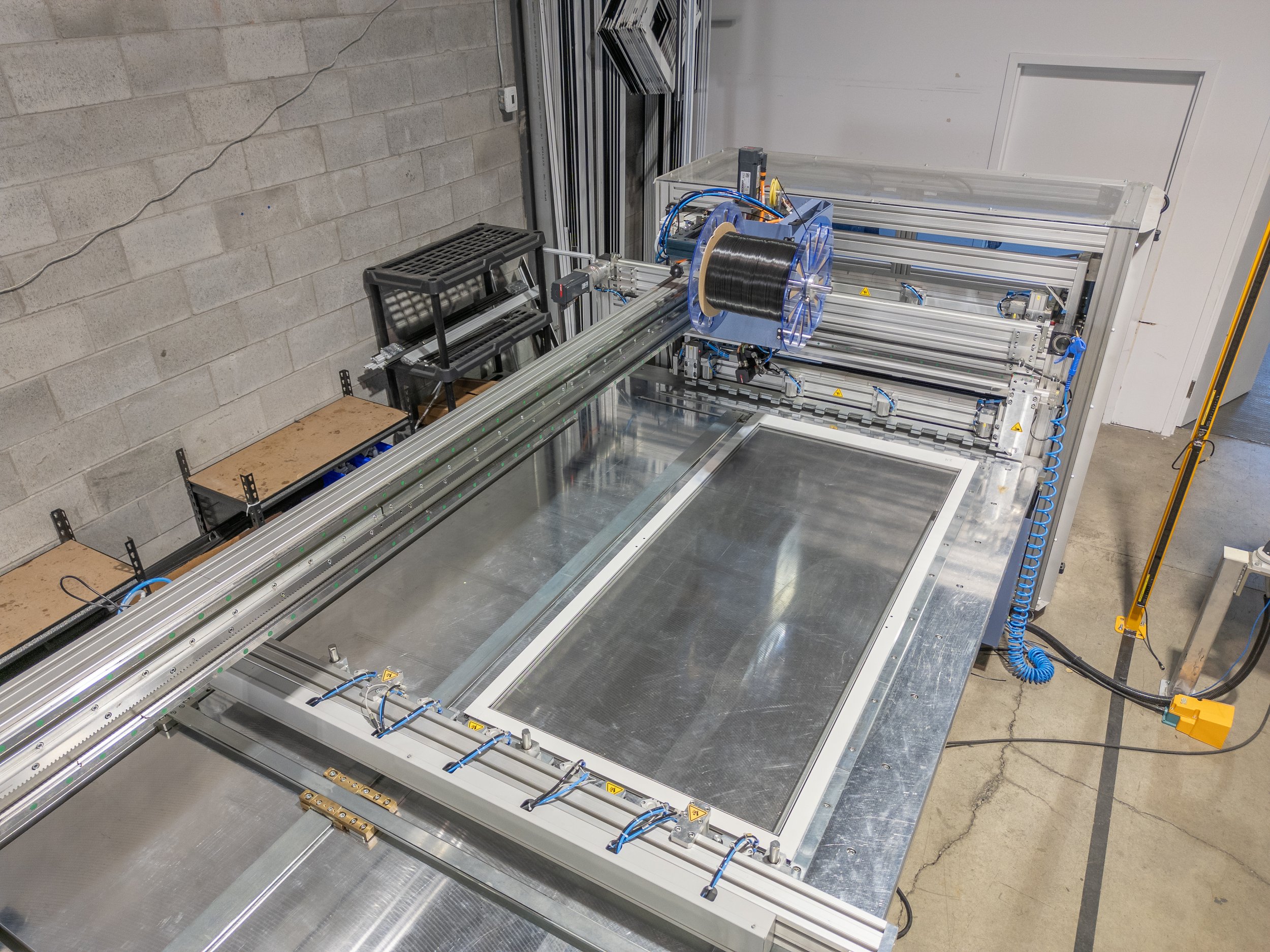

Expanding our capabilities with the SAC-855

The AUTOSCREEN™ SAC-845 and SAC-855 Mesh/Spline Insertion & Trim machines automate the application of screen mesh to a pre-assembled screen frame. They both utilize bar code/QR code scanning or direct ERP input to identify the screen frame, automatically choose and apply the correct screen mesh, insert the screen spline, and trim excess perimeter screen mesh.

With the expansion of the SAC-855 model, the AUTOSCREEN™ machine can now accommodate larger sizes such as patio doors. The estimated typical cycle time for an average 48” x 96” patio door screen frame is approximately 80 seconds, including all handling and only one operator.

Sizing & Specifications

Machine footprint: 10’x 15’ (includes safety zone)

Voltage: 400 VAC, 10 amps, wired internet connection required

Screen spline diameter: 0.12” to 0.200”

2 position screen mesh applicator to optimize utilization & reduce scrap

Multiple Materials: Polyester, fiberglass, aluminum or PVC

Input via bar code or QR code scan, ERP file, directly on HMI screen

Air pressure: 4-6 bar

Minimum frame size SAC-845 and SAC-855: 15” x 15”

Maximum frame size SAC-845: 30” x 60”

Maximum frame size SAC-855: 48'' x 96''

FEATURES:

- Out of tolerance detection for screen frame assembly

- Hour glass adjustment on mesh

- Screen track deviation detection (release November 2024)

- Remote camera and data monitoring and reporting

Interested in AUTOSCREEN?

Get a custom consultation and see how the AUTOSCREEN machines can boost your facilities.